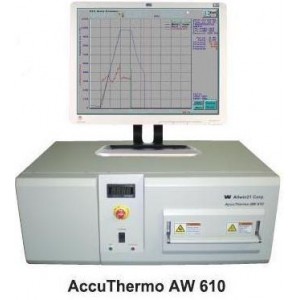

Rapid Thermal Process Accuthermo AW610

Closed-loop temperature control with pyrometer or thermocouple temperature sensing. Precise time-temperature profiles tailored to suit specific process requirements. Fast heating and cooling rates, Consistent wafer-to-wafer process cycle repeatability. Elimination of external contamination. Small footprint and energy efficiency. ?